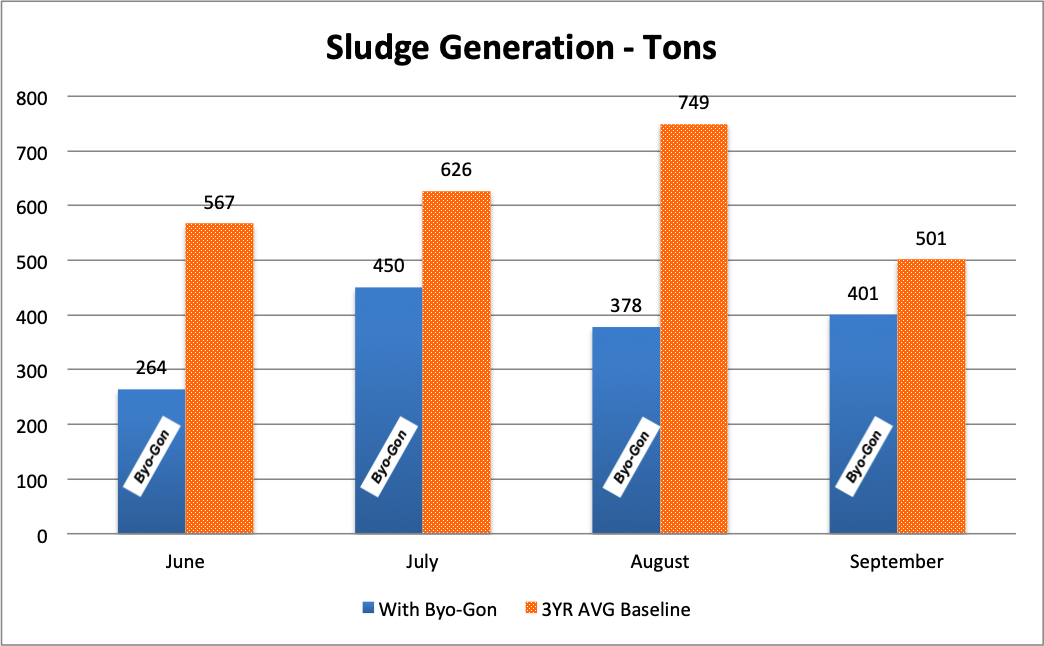

A Kraft paper mill in New York needed to reduce their sludge generation because their onsite landfill was filling quicker than planned. The mill has evaluated many options to reduce secondary sludge volume over the years and has been unsuccessful in finding a solution. In early 2018 a project was started to apply Byo-Gon PX-109 into the influent to the secondary activity activated sludge treatment system.

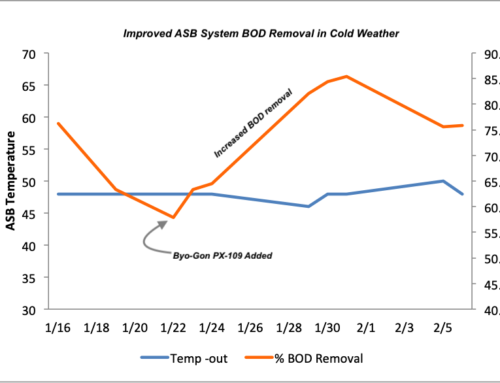

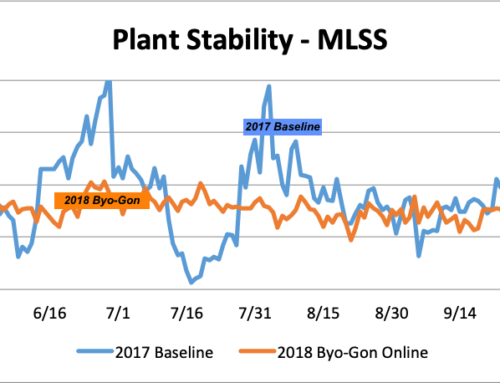

Byo-Gon PX-109 works to increase microbial activity and drive BOD removal performance – resulting in a more efficient conversion of soluble BOD without excess secondary sludge. As the product is incorporated into the wastewater, the system cellular energy is increased (measured by cellular ATP) and biological reactions are driving to completion. Mill staff began measuring ATP daily to confirm elevated performance and to evaluate shock loads to their system. They now evaluate biological activity (%ABR) and stress level (%BSI) to ID mill discharges that impact wastewater treatment.

Sludge yield (lb. sludge/lb. BOD influent) has decreased to 0.8 this summer compared to over 1.0 previously. Optimization of MLSS levels and recycle rates now can be conducted at higher microbial activity to further drive down sludge production. Optimization will continue into 2019 to further improve sludge yield.